Industrial Angle Grinder Repair

Up

Up

This page details my work on repairing a 7" industrial angle grinder  . I got it for $10 at an auction and it spent a while in my pile of broken tools awaiting repair. Now that I had some time to waste, and did not want to throw it away, I decided to give it a look.

. I got it for $10 at an auction and it spent a while in my pile of broken tools awaiting repair. Now that I had some time to waste, and did not want to throw it away, I decided to give it a look.

It obviously has seen a long and tough life and was at some point

dropped, had a handle broken and repaired by semi decent welding, and

also lost a switch.

When powered up, it produced a gigantic spark and died.

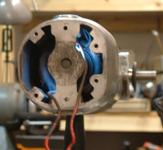

I opened it up. To open it up, I had to make a slit in one of the

screws that had its philips end stripped out, and remove it with a

flat screwdriver.

I had a similar experience before with a 450 RPM drill  . It's the carbon dust inside that shorts something

brush-related. Without thinking too much, just as I did with the

drill, I blew out the dust inside with compressed air. It worked.

. It's the carbon dust inside that shorts something

brush-related. Without thinking too much, just as I did with the

drill, I blew out the dust inside with compressed air. It worked.

I found a suitable power cord in my junk pile. I drilled and tapped

a hole in the handle using A 1/4" drill and a 5/16"-18 NC tap, and

used a screw to hold the cable.

I inserted the cable and connected it to the drill. Please note

that this setup is missing the necessary power switch, so this drill

will have to be run from a foot switch or some such, until I identify

what it is.

Here, pictures tell us the story.

(Click on the thumbnail images to enlarge)

. I got it for $10 at an auction and it spent a while in my pile of broken tools awaiting repair. Now that I had some time to waste, and did not want to throw it away, I decided to give it a look.

. I got it for $10 at an auction and it spent a while in my pile of broken tools awaiting repair. Now that I had some time to waste, and did not want to throw it away, I decided to give it a look.

Up

Up . I got it for $10 at an auction and it spent a while in my pile of broken tools awaiting repair. Now that I had some time to waste, and did not want to throw it away, I decided to give it a look.

. I got it for $10 at an auction and it spent a while in my pile of broken tools awaiting repair. Now that I had some time to waste, and did not want to throw it away, I decided to give it a look.

. It's the carbon dust inside that shorts something

brush-related. Without thinking too much, just as I did with the

drill, I blew out the dust inside with compressed air. It worked.

. It's the carbon dust inside that shorts something

brush-related. Without thinking too much, just as I did with the

drill, I blew out the dust inside with compressed air. It worked.